In fall 2020, the German Electron Synchrotron (DESY) in Hamburg provided one week of experimental time to the scientists of the Institut für Strahlwerkzeuge (IFSW) and the Lehrstuhl für Lasertechnik (LLT) in Aachen.

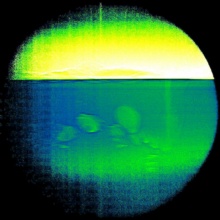

The high-quality X-ray beam enabled sensational insights into the various laser material processing processes of welding, cutting and selective laser beam melting. The investigations with the monochrome X-ray beam are not limited to the distinction between the gaseous and the solid material, which results from the different densities. The different optical properties of the aggregate states lead to a phase contrast, which allows to identify the transitional locations between liquid and solid material. This allows to capture the dimensions of melt pools during welding and melt films during cutting within the material during the process.

Two exemplary results of this investigation are now freely available via the DaRUS database of the University of Stuttgart and can be properly cited via the corresponding doi. The first video (https://doi.org/10.18419/darus-2078) shows the two different laser beam welding modes of heat-conduction welding and deep-penetration welding. The video presents heat-conduction welding as a stable process with low penetration depth but high weld quality, while deep-penetration welding results in high penetration depths but is associated with fluctuations of the keyhole and formation of pores. The second video (https://doi.org/10.18419/darus-1824) shows the process of laser fusion cutting. For the first time, the captured images allow the direct measurement of the thickness of the melt film during a laser beam cutting process.

Another publication (https://doi.org/10.3390/met11050797) presents an analysis of such X-ray videos on the effect of evaporation of volatile alloying elements on the keyhole geometry during welding of aluminum alloys.

Watch the videos also on our YouTube channel at:

https://www.youtube.com/watch?v=_p0uvyWdUr0

https://www.youtube.com/watch?v=I4DK9O4exzg

Contact: Dr. Christian Hagenlocher