Scientists from the Institut für Strahlwerkzeuge (IFSW) at the University of Stuttgart used the particle accelerator at the German Electron Synchrotron (DESY) in Hamburg to observe laser beam processes in real time using state-of-the-art X-ray radiation techniques and obtain detailed information about the processes at the microscopic level.

The use of lasers in manufacturing is ubiquitous nowadays. The versatile application possibilities, ranging from cutting, drilling, structuring, welding and soldering to additive processes and covering all conceivable materials such as metals, glasses, plastics or organic materials, make the laser irreplaceable as a tool for manufacturing.

Thanks to advances in laser development, very powerful laser devices are available today. For laser material processing, this means that welding speeds or drilling depths can be increased, for example. The increasing performance of lasers also leads to increased efficiency and productivity of industrial applications. Processes that used to take a lot of time can now be accelerated significantly. This allows companies to save costs and improve overall profitability.

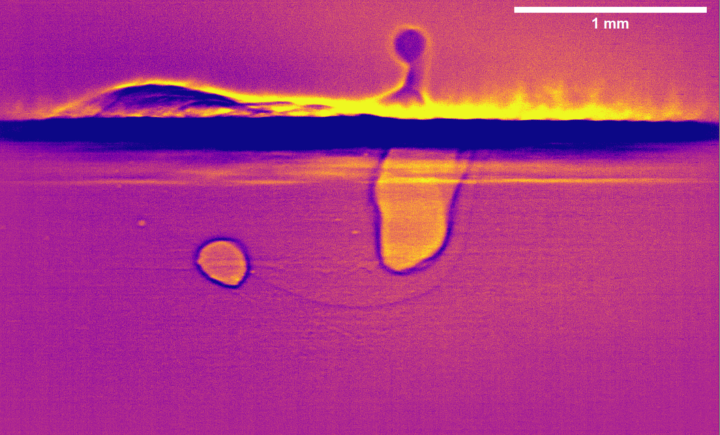

With the increases mentioned, however, process defects such as pores, spatters, cracks or other process instabilities must be avoided. Insight into the process itself helps to achieve this. The ideal means for this is X-ray videography, in which the sample is transilluminated with X-rays during the process and recorded with a high-speed camera.

Thanks to a joint application by the Fraunhofer ILT, the Chair of Photonic Technologies (FAU Erlangen-Nuremberg), the Production Technology Group (TU Ilmenau) and the IFSW, beam time was successfully obtained at the DESY. The particle accelerator in Hamburg is one of the most powerful storage ring X-ray sources in the world and enables the observation of laser machining processes with a local resolution of a few micrometres. The recording rate reaches 18,000 frames per second for aluminium samples. The coherent X-rays also make it possible to visualise the boundaries between solid and liquid material, revealing the area of molten metal.

The experimental campaign in April 2023 was already the third of a total of four and extended over a week in 24-hour shift operation so that every minute of beam time is used for a wide range of experiments.

Contact: Felix Zaiß