In summer 2021, the IFSW will start the research project ADDSUB together with its partners from the LAZ of the Aalen University of Applied Sciences and the wbk of the Karlsruhe Institute of Technology. The common goal of this research group is to significantly increase the efficiency of a transverse flux machine - an electric motor for wheel hub drives - through interdisciplinary technological as well as scientific cooperation.

The IFSW is developing the necessary laser-based manufacturing technology for this purpose. By combining additive and subtractive processes on one and the same machine, it is aimed to realize previously unattainable filigree, internal hollow microstructures to reduce magnetization losses in topologically optimized soft magnetic components.

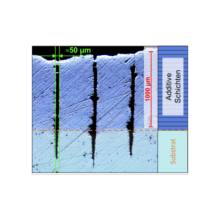

With the additive 'Laser Powder Bed Fusion' process, soft magnetic components can be manufactured with unrivaled design freedom. To increase the efficiency, torque, and power density of the E-machines, the volume fraction of the soft magnetic material compared to the hollow structures must be maximized and therefore the width of the insulating cavities must be reduced significantly below the level of approx. 100 µm currently reproducible with additive processes. This shall be achieved by generating highly precise micro-hollow structures between the consecutive additive buildup of material layers by a controlled ablation process using ultrashort laser pulses.

The first step towards integrating the additive and subtractive processes on one machine has already been taken at the IFSW and the results are impressive [1]. This approach is a successful example of the enormous potential that lies in combining and integrating different laser processes in one and the same system, which goes significantly beyond the mere concatenation of laser-based manufacturing technologies. Against this background, the ADDSUB project provides an important building block for the vision of a universal machine that unites and ideally combines processes from all six main groups of manufacturing processes as defined by DIN 8580: The production system of the future [2].

[1] Henn M., Buser M., Onuseit V., Weber R., Graf T.: Combining LPBF and ultrafast laser processing to produce parts with deep microstructures. In: Lasers in Manufacturing Conference 2021, Munich

[2] Graf T., Hoßfeld M., Onuseit V. (2021) A Universal Machine: Enabling Digital Manufacturing with Laser Technology. In: Weißgraeber P., Heieck F., Ackermann C. (eds) Advances in Automotive Production Technology – Theory and Application. ARENA2036. Springer Vieweg, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-62962-8_45

Contact: Matthias Buser and Manuel Henn