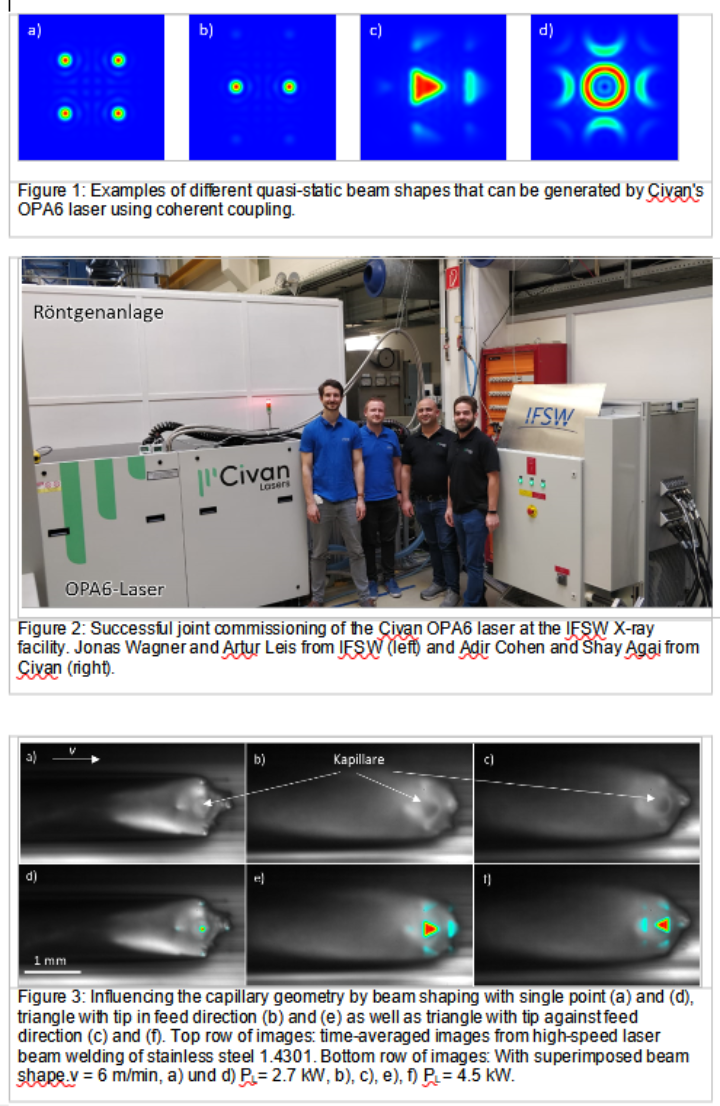

Civan's OPA6 laser makes the beam shaping technology of coherent coupling of multiple fibre lasers available for laser welding for the first time. This technology enables the flexible generation of a multitude of different, quasi-static intensity distributions, as well as their dynamic modulation and combination in frequencies of up to several MHz. This opens up enormous possibilities for new control variables to influence the welding process in a targeted manner. Figure 1 shows an example of the quasi-static intensity distributions of different beam shapes that can be generated with the OPA6 laser.

In order to be able to use these novel variables in a systematic manner for process optimisation, the interaction of such dynamically modulated laser beams with the material must be fundamentally investigated.

For this purpose, an OPA6 laser was successfully integrated into the online X-ray facility of the IFSW as part of a cooperation with Civan (see figure 2).

Using the high-speed X-ray images, the dynamic behaviour of the capillary in the welding process can be analysed, and three-dimensional reconstructions of the geometries of the capillary can be extracted. In combination with the IFSW's own ray tracing software this enables the analysis of the influence of the dynamic beam shaping on the energy input. This was shown for the first time as an example in [1]. In combination with other diagnostic tools such as the measurement of the back reflection, optical coherence tomography (OCT), high-speed imaging of the capillary’s opening, the melt pool surface and the formation of spatters as well as the measurement of thermal radiation and subsequent metallographic analyses, a holistic view of the chain of effects from the energy input to the resolidification and the formation of the microstructure in the weld seam is possible. In the upper row Figure 3 shows time-averaged images from high-speed recordings that illustrate the potential for shaping the geometry of the capillary by means of beam shaping. In the bottom row, the images are overlaid with the quasi-static intensity distribution used in each case, which illustrates the high degree of agreement between the set and observed capillary geometry.

First investigations have already been presented at the IIW 2022, SLT 2022 as well as LANE 2022 conferences and published in [1,2] and show the high potential of dynamic beam shaping for dynamic modulation of the capillary’s geometry.

[1] Wagner, J.; Leis, A.; Armon, N.; Nissenbaum, A.; Hagenlocher, C.; Holland, J.; Weber, R.; Graf, T. Coherent beam combining – unlimited flexibility in laser material processing. PhotonicsViews 2022, 19, 60–63, doi:10.1002/phvs.202200024.

[2] Wagner, J.; Heider, A.; Ramsayer, R.; Weber, R.; Faure, F.; Leis, A.; Armon, N.; Susid, R.; Tsiony, O.; Shekel, E.; et al. Influence of dynamic beam shaping on the geometry of the keyhole during laser beam welding. Procedia CIRP 2022, 111, 448–452, doi:10.1016/j.procir.2022.08.185.