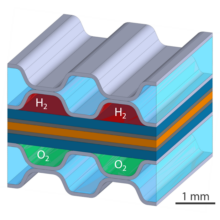

Together with its partners - the wbk Institute of Production Science and the IPEK Institute of Product Engineering at the Karlsruhe Institute of Technology - the IFSW is researching new flow structures for more efficient polymer electrolyte membrane (PEM) fuel cells.

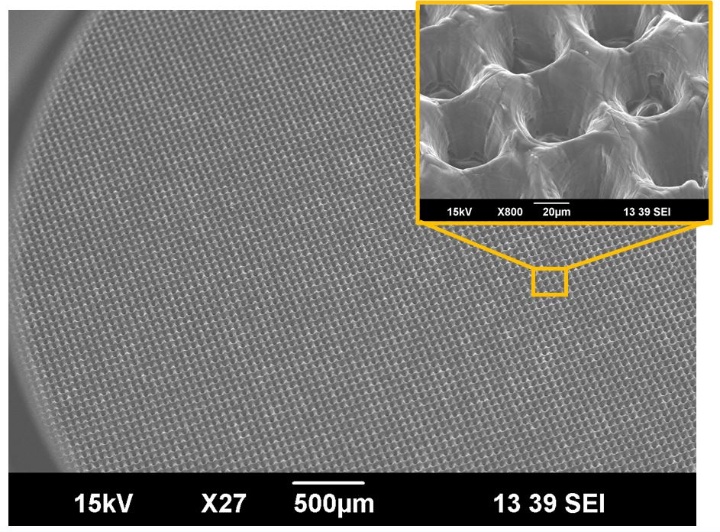

In a first step, laser holes were drilled into a 40 µm thin graphite foils on a large scale. By selecting suitable parameters, more than 15’000 holes with an average diameter of 45 µm could be generated per minute in a very small space (see SEM image). The foils perforated in this way enable basic experimental the investigations of optimized flow conditions within the gas diffusion layer of fuel cells with the aim of improving their efficiency and service life.

The work was carried out as part of the EM4 AddPEM project of the InnovationCampus Mobility of the Future (ICM). We would like to thank the Ministry of Science, Research and the Arts Baden-Württemberg (MWK) for funding the project within the ICM.

Contact: Matthias Buser